All our processes are completed in-house to a factory standard. Not to be confused with a quick spray paint or a cosmetic repair our process is the only way to have your wheels refurbished correctly. Carried out over several working days all wheels are chemically stripped and reworked to ensure a finish that rivals new wheels.

Tyre removal

All tyres are removed from wheels along with valves and balancing weights. Once the tyres are removed they are inspected for any wear or structural damage that could affect the integrity of the tyre, when required we are able to supply new tyres at very competitive prices. The wheels are also inspected for any structural damage such as bends or cracks caused by potholes or speed bumps. Any findings are reported and the customer is advised on the best course of action. Before the wheels move on to the next stage they are allocated a job number to enable us to identify them at any point of the process.

Chemical stripping

All wheels that pass through our workshop are chemically stripped to remove all the old existing coating. The wheels are submersed in a heated chemical solution that gently removes coatings and allows us access to the bare aluminium wheel. Once the stripping process has taken place it gives us a clear indication of the integrity of the wheel and what damage needs addressing.

Bend Repair

After the wheels are stripped any bend repairs are carried out, we do this after the stripping process as it allows us to identify any stress fractures that may have occurred when the wheel was damaged.

Blasting Process

The start of the prep process involves the wheels being media blasted in our automated machine. This is done to remove any residue left from the stripping process plus any corrosion on the wheel and to give the wheel a keyed surface which provides better adhesion for the new powder coat that is applied.

Once the wheels are blasted they are moved on to the prep area where we start the process of removing any damage.

Prepping the wheel

Every wheel is prepared by hand before the coating process. This will sometimes involve welding badly damaged wheels but more often than not we can remove the damage using sanding and filing techniques by hand. We continue to inspect the wheels through the various stages to ensure nothing has been overlooked, our aim is to achieve the best possible finish on the final product and give our customers piece of mind.

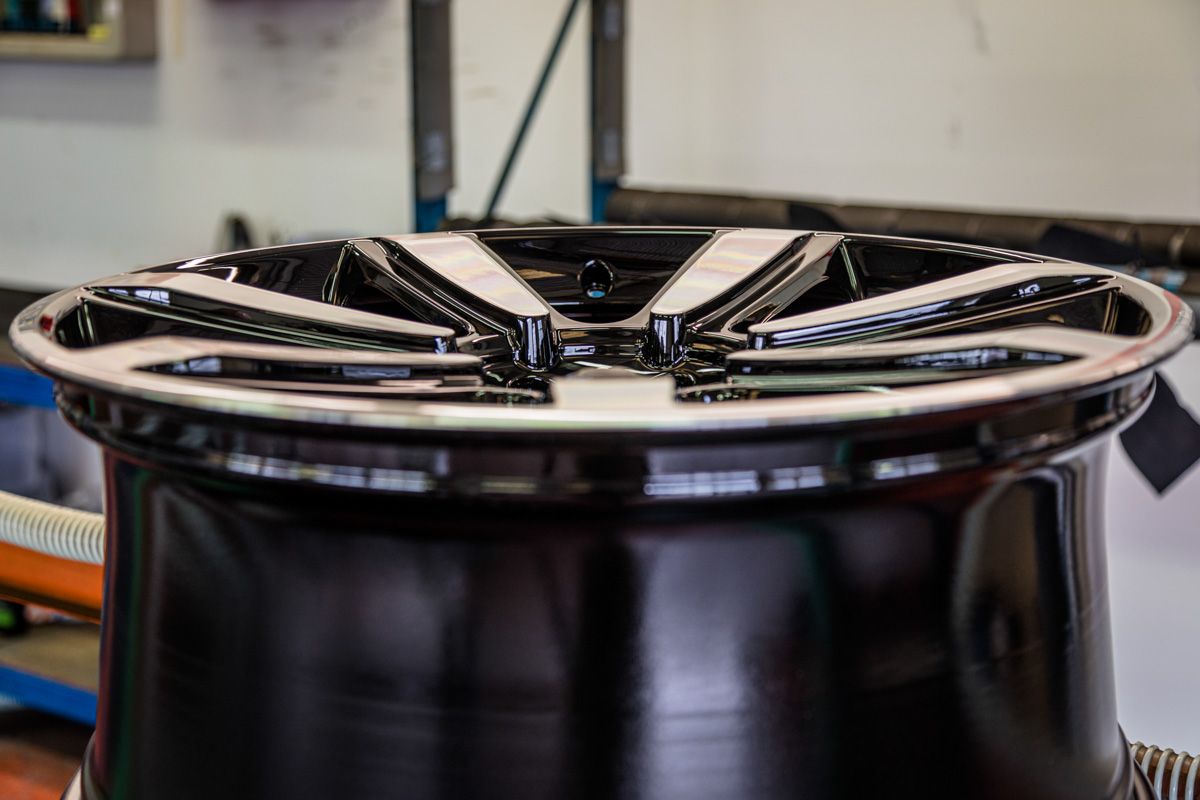

Coating Process

After the wheels have been inspected and prepped they are loaded onto our coating line ready for the various stages. Before the first stage the wheels are pre heated to the required temperature to allow application of the primer coat.

After the powder coat primer has been applied the wheels pass through the oven for the curing process. Once the wheels have cured over a determined time and temperature they exit the oven onto a cooling loop where they are inspected before passing into the paint booth for colour application. Colours are applied using paint guns, due to the temperature of the wheels the paint is able to dry before passing through to the lacquer booth. Acrylic powder coat lacquer is applied to the whole wheel before passing into another oven for the curing process.

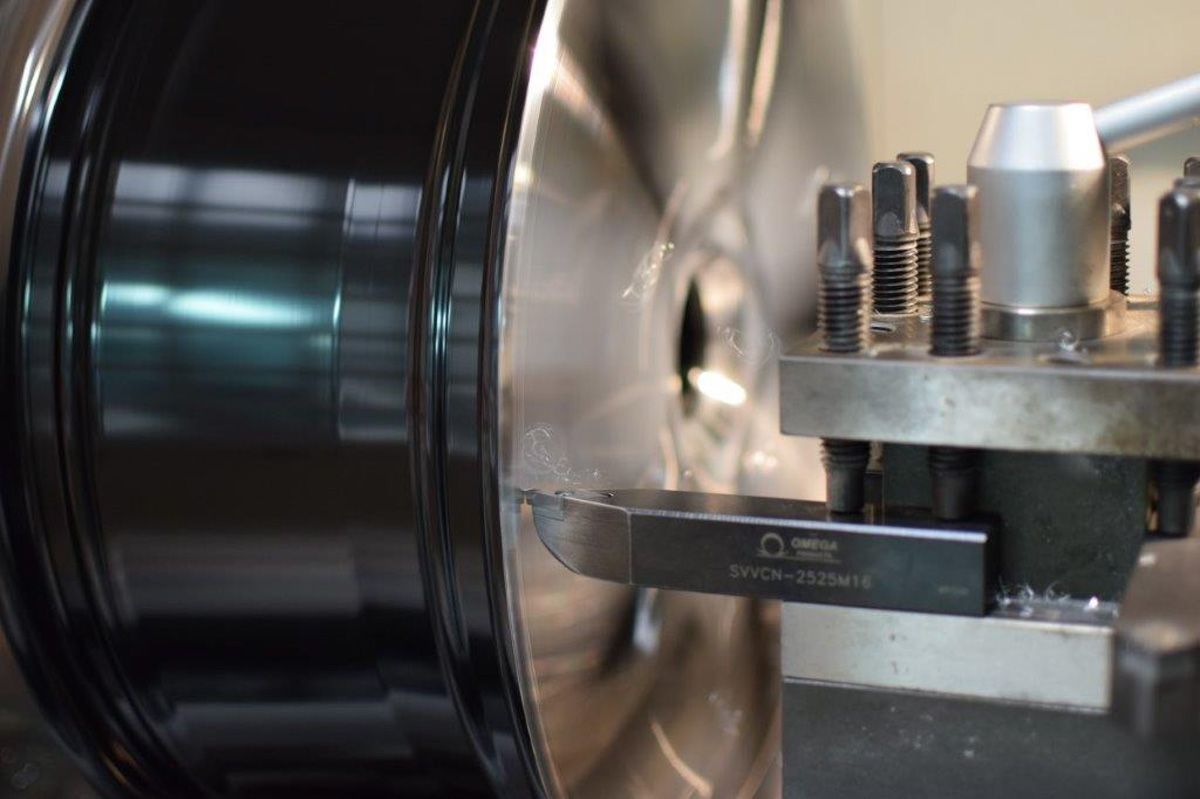

Diamond Cut

Wheels that require a diamond cut finish are removed from the coating process once the colour has been applied and cured. We run several CNC lathes to carry out this process which allows us to cut multiple wheels in a day. We are able to record and store the profiles of 1000’s of wheels, all of which are accurately probed to ensure the smallest amount of material is removed from the wheel during the cutting process. Once the wheels have a smooth uniform finish they are hand finished to remove any burred edges and degreased before being loaded back onto the coating line for lacquer application.

Quality Control

The wheels are left to cool after the coating process and taken through to our QC area for final inspection. Any imperfections are lightly flattened off with ultra-fine sanding paper and polished to leave a flawless finish. Once the wheels have been signed off by our workshop manager they are ready to have the tyres fitted and balanced.

Tyre Fit and Balance

All tyres are identified via a job number which matches the wheels they came off. Any new or existing tyres are refitted and balanced with new rubber valves. Any metal valves can be supplied and fitted by us at a small additional cost. Once fitted up the wheels are given one final inspection and signed off.

Conclusion

The process above is a brief outline of what goes into the refurbishment of alloy wheels that pass through our workshop. We feel this is the ONLY way to repair wheels to a safe and high standard that replicates the factory finish.